White PC 1.75mm 3kg PolyMax Tough Polymaker

| Brand: Polymaker |

| Color: White |

| Weight: 3Kg |

| Diameter: 1.75mm |

| Material: PC |

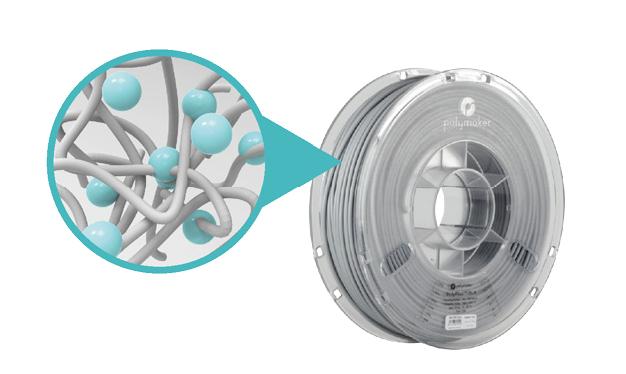

PolyMax PC

PolyMax is a family of advanced 3D printing filaments produced with Polymaker’s Nano-reinforcement technology, to deliver exceptional mechanical properties and printing quality.

PolyMax PC is an engineered PC filament combining excellent strength, toughness, heat resistance and printing quality. It is the ideal choice for a wide range of engineering applications.

Does PolyMax PC need to be annealed?

Annealing is the process of heating up the printed parts at a certain temperature for a certain period of time. You can anneal PolyMax™ PC at 90˚ for 2h.

The purpose of annealing PolyMax™ PC is to release the internal stress which accumulates during the printing process. This internal stress can creates micro cracks over time and weaken the part.

(NOTE: In the case of semi-crystalline polymers such as Nylon, annealing purpose is mainly to crystalize the material for better mechanical and thermal properties)

What is the best surface adhesive for PolyMax PC?

In our experience we had excellent experience with Magigoo PC. This special glue allows great adhesion when the build plate is hot and easy release when the build plate cools down.

Printing Settings

Printing Temperature: 250˚C - 270˚C

Bed Temperature: 90˚C - 105˚C

Printing Speed: 30mm/s - 50mm/s

Fan: OFF

Direct Drive:

Retraction Distance: 1mm

Retraction Speed: 20mm/s

Indirect Drive:

Retraction Distance: 3mm

Retraction Speed: 40mm/s

When printing with PolyMaxPC it is recommended to use an enclosure. For large part it is recommended to use a heated chamber.

Drying Settings: 75˚C for 12h

(Only if the material has absorbed moisture)

Annealing Settings: 90˚ for 2h

Mechanical Properties

Young's Modulus:

2048 ± 66 Mpa

Tensile Strength:

59.7 ± 1.8 Mpa

Bending Strength:

94.1 ± 0.9 Mpa

Charpy Impact Strength:

25.1 ± 1.9 kJ/m2

Thermal Properties

Glass Transition Temperature:

113˚C

Vicat Softening Temperature:

117˚C

Melting Temperature:

N/A˚C